Do you have questions? Please contact:

Jörg Bander

Sales composite panels

Tel.:

+49 (0) 2773/815-306 -

Email

Lightweight, stable and thermally insulating sandwich panels for ceilings, walls and floors of modern commercial vehicles.

Ceilings, walls, doors and floor panels of modern vehicle bodies are largely manufactured using sandwich panels. Compared to conventional metal constructions, they offer significant weight reduction combined with excellent thermal insulation.

Depending on requirements and application, we design the appropriate panel using a wide range of material combinations.

Dimensions, core materials and facings are adapted on a project-specific basis to the respective vehicle application.

Depending on the installation situation, different requirements on our lightweight building units can result. Therefore, specific material combinations are required.

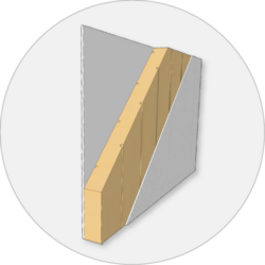

Sandwich Panels for Ceilings

Key requirements for ceiling elements are low weight and high mechanical stiffness.

Typical Panel Structure (Example):

Properties:

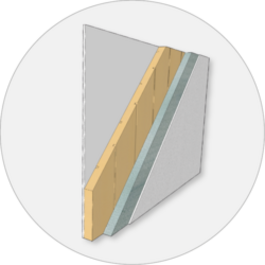

Sandwich Panels for Side Walls

Side walls ensure the structural stability of the entire box body. Depending on the application, additional requirements such as thermal insulation or screw retention may be relevant.

Typical Panel Structure (Example):

Properties:

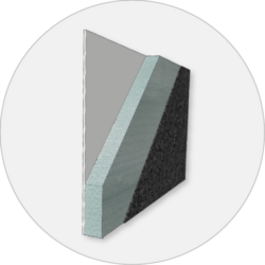

Sandwich Panels for Floors

Despite their low weight, floor panels must offer high mechanical strength and good wear resistance. These requirements are met through suitable core materials and facings.

Typical Panel Structure (Example):

Properties:

Sandwich Panels COSMO® Therm - GFK

GRP on both sides, PUR core

Composite panels consisting of glass reinforced platic (GFR) with a thickness of 2,0mm and a core of extruded polyurethane foam (PUR).

Sandwich Panels COSMO® Therm - PVC (WLG 030)

PVC on both sides, XPS core

Composite panels consisting of a PVC compact panel with a thickness of 1,0 - 2,0mm and a core of extruded polystyrene foam (XPS). Thermal conductivity: 030.

Sandwich Panels COSMO® Tech - GFK

GRP on both sides, TK-core

Composite panel with outstanding mechanical characteristics. Environment-friendly core material (100% recyclable)

Sandwich Panels COSMO® Tech - GFK antislip

Composite panel with minimum absorption of humidity and outstanding mechanical characteristics

Sandwich Panels COSMO® Tech - GFK

Screen printing panel on one side, TK core, GRP on rear side

Composite panel with outstanding mechanical characteristics. Floor element in automotive manufacturing

For the assembly and sealing bonding of our elements in the field of automotive manufacture we recommend our 2-C-STP Construction Adhesive COSMO® HD-200.101

2-component STP-assembly adhesive

The controlled

Elastic 2-component STP-adhesive for a multitude of assembly bonding applications, with homogeneous through-hardening and reliable process time during the application.

Do you have questions? Please contact:

Jörg Bander

Sales composite panels

Tel.:

+49 (0) 2773/815-306 -

Email

More information